(1) GENERAL INFORMATION

|

FACULTY |

APPLIED TECHNOLOGIES |

||

|

DEPARTMENT |

AIRCRAFT TECHNOLOGY ENGINEERING |

||

|

LEVEL OF STUDIES |

UNDERGRADUATE |

||

|

MODULE CODE |

AE2240 |

SEMESTER OF STUDIES |

4TH |

|

COURSE TITLE |

AIRCRAFT MAINTENANCE PRINCIPLES |

||

|

INDEPENDENT TEACHING ACTIVITIES |

TEACHING HOURS PER WEEK |

CREDIT UNITS |

|

|

Lectures and Practice |

3 |

4 |

|

|

Lab activities |

2 |

2 |

|

|

|

|

|

|

|

|

|

|

|

|

COURSE TYPE

|

Specialty course |

||

|

PRE-REQUIRED COURSES:

|

|

||

|

TEACHING AND EXAMINATION LANGUAGE |

GREEK |

||

|

THE COURSE IS OFFERED TO ERASMUS STUDETNS |

|

||

|

COURSE WEBSITE (URL) |

|

||

(2) LEARNING OBJECTIVES

|

Learning Objectives |

|

|

|

|

|

After successfully completing the course, students should be able to: |

|

|

GENERAL SKILLS |

|

|

|

|

|

|

|

|

1) Autonomous work 2) Group work 3) Work in an international environment

|

|

(3) COURSE CONTENT

|

Unit 1: Aircraft Safety measures – Tools and equipment Safe work methods including protection measures that must be taken while working with electricity, gases and particularly oxygen, oils and chemicals. Directions for corrective actions in case of fire or any other emergency Unit 2: Service Practices Tool maintenance, tool check, usage of service materials Dimensions, supplies, tolerances, quality work standards Τοol and equipment calibration, calibration standards Unit 3: Tools Common manual tools, Common power tools, Operation and usage of precision measurement tools, Lubrication equipment and methods, Operation and usage of general test power equipment Unit 4: General Test Electronic Equipment Operation and usage of general test electronic equipment Unit 5: Engineering Drawing, Diagrams and Prototypes Drawing types and diagrams, their symbols, dimensions, tolerances and projections Recognition of information control system title, Microfilm, microfiche and computerized presentations, ATA specification 100 , Wiring digrams and schematic diagrams. Unit 6: Assemblies and clearances Drill sizes for screw holes, joints , Common joint clearance system , Joint clearance program for aircraft engines, Arrow limits, twist and wear, Standardized methods for shaft check, bearings and other parts. Unit 7: Electric cables and connections Galvanic continuity, insulation and connection techniques and testing, Usage of crimping tools: manual and hydraulic, Folding joint test, Removal and insertion of connecting dowel, Coaxial cables: testing and installation precautions Wiring protection techniques: Apparent wire deformation and coating support, cable clamps, protective techniques for ring type connections including windings due to thermal contraction and shielding. Unit 8: Riveting Riveted connections, rivet distance and step, Tools used for riveting and deformation, Inspection of riveted connections. Unit 9: Pipes and hoses Aircract tube bending and stretch , Aircraft tube and hose inspection and testing, Installation and connection of tubes with clamps Unit 10: Springs Spring inspection and testing. Unit 11: Bearings Testing, cleaning and inspection of bearings Bearing lubrication requirements , Bearing failure and their cause. Unit 12: Motion transmission systems Wheel inspection system, Inspection of belts and pulleys, chains and gears, Inspection of screw jacks, lever devices, push- pull rod systems Unit 13: Control cables Extreme application development, Control cable inspection and testing, Bent cables: aircraft flexible control systems Unit 14: Sheet metal treatment Determination and calculation of sheet metal limitations, Sheet metal treatment, including bending and shaping, Inspection of metal sheet treatment. 15η Ενότητα: Soldering, Brazing, Welding and Bonding, Soldering methods: soldered joints inspection, Welding and brazing methods, Inspection of welded and brazed joints, Integration methods and inspection of bonded joints. 16η Ενότητα: Aircraft weight and balancing , Aircraft preparation for weighing, Aircraft weighing. Unit 17: Aircraft Ground Service and Storage Aircraft taxiing/towing and relevant safety precautions, Aircraft lifting with jacks, bonding, securement and relevant safety precautions, Aircraft storage procedures , Supply procedures / fuel pumping, Deicing/anti icing procedures, Electric, hydraulic and pneumatic ground equipment, Environmental conditions affecting aircraft ground service and operations. Unit 18: Disassembling, Repair and Reassembling procedures Types of failure and visual inspection techniques, Corrosion elimination, valuation and re-protection General repair methods, Construction Repair manual, Aircraft aging/fatigue/corrosion control programs, Non destructive control techniques including penetrating liquid techniques, radiography, self induction , ultrasound and endoscope Disassemply and reassembly techniques Problem location and repair techniques. Unit 19: Unusual incidents Inspections following thunderbolts and High Intensity Radio transmission field penetration. Inspections following unusual incidents such as heavy landings and turbulent flights. Unit 20: Maintenance Procedures Maintenance scheduling, Alteration procedures, Material procedures, Certification procedures and delivery, Interaction with aircraft operation, Maintenance/quality control/quality assurance inspection Additional maintenance procedures, Component life span control. Unit 21: Propeller maintenance Static and dynamic balancing, Flap track, Flap damage assessment, corrosion, oxidation, impact wear, Propeller maintenance scheduling,

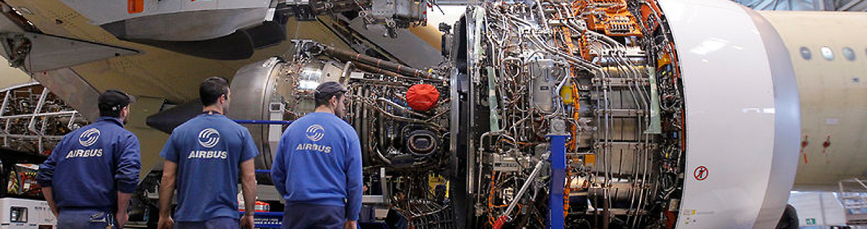

1st lab activity: Bearings inspection, cleaning, lubrication and testing 2nd lab activity: Motion transmission systems inspection 3rd lab activity: Control cable inspection and testing 4th lab activity: Metal sheet treatment methods and treatment inspection 5th lab activity: Welding methods and welding inspection 6th lab activity: Weight calculation and aircraft balancing 7th lab activity: Aircraft ground servicing techniques 8th lab activity: Aircraft engine inspection, disassembly, repair and re-assembly techniques 9th lab activity: Non destructive control techniques 10th lab activity: Propeller maintenance and repair

|

|

|

(4) TEACHING AND LEARNING METHODS - EVALUATION

|

ΤEACHING METHOD |

In the classroom |

||||||||||||||||

|

USE OF INFORMATION AND COMMUNICATION TECHNOLOGIES |

Use of e-class platform |

||||||||||||||||

|

TEACHING ORGANIZATION

|

|

||||||||||||||||

|

STUDENT EVALUATION

|

Final writen examination (100%) including: - Multiple choice questions - Problem solving questions on specific maintenance cases |

(2) SUGGESTED BIBLIOGRAPHY

|

-Suggested Bibliography : 1) Καραγκιόζογλου Γεώργιος, “Στοιχεία υπολογισμού, κατασκευής και συντήρησης αεροσκαφών”, Εκδόσεις Ζαμπάρα 2006 2)www.faa.gov/regulations_policies/handbooks_manuals/aircraft/ -Συναφή επιστημονικά περιοδικά:

|